Substrate Wetting

- Andy Richards

- Jun 5, 2020

- 2 min read

Updated: Sep 30, 2021

When a drop of liquid is placed on a surface it can either:

Spread over the surface – it therefore ‘wets’

Form a stable drop – it is unable to ‘wet’

Reduction in surface tension of water by addition of a surfactant can make a non-wetting solution into a wetting solution on particular substrates. The ability to wet or not depends upon the surface tension of the solution and the critical surface tension (CST) or surface energy of the solid. The CST is the surface tension of a liquid which will form a contact angle of close to zero measured across the film on that solid, i.e. the liquid spreads over the solid. Glass, with a CST of more than 70 dynes/cm can be wet easier than polypropylene, with a CST of 28. In all cases to wet a substrate quickly and effectively, a surfactant will be required to help reduce the surface tension and overcome the surface energy of the substrate.

The surface energy of different substrates vary. High energy substrates are easier to wet than low energy substrates.

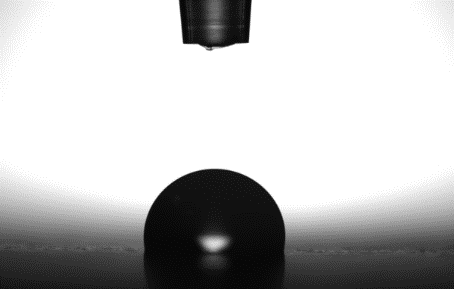

The diagram below shows the relationship between the surface tension of a droplet onto a substrate surface and the contact angle. The shape of a liquid-vapour interface is determined by the Young–Dupre equation, with the contact angle playing the role of a boundary condition via the Young equation.

The simplified equation is: cos Θc = ϒSL – ϒSG / ϒLG ϒSL = Solid–liquid interfacial energy ϒSG = Solid–vapour interfacial energy ϒLG = Surface tension

The conclusions that can be drawn are:

A substrate with high surface tension is easily wetted

A liquid with a low surface tension wets a substrate easily

In all cases to wet a substrate quickly and effectively, a surfactant will be required to help reduce the surface tension of the droplet or liquid low enough to overcome the surface energy of the substrate.

Surface Energy of Substrates

Substrate | Surface Energy - mN/m |

Copper | ~1000 |

Aluminium | ~500 |

Glass | 290 |

Stainless steel | 53 |

Lino | ~45 |

Polycarbonate | 44 |

Nylon 6 | 43.9 |

Nylon 66 | 42.2 |

PET G | 39 |

Rigid PVC | 37.9 |

PE 1000 | 31.6 |

Acetal | 31 |

Polypropylene | 30.5 |

PTFE | 19.4 |

Static contact angle measurement

One of the most popular ways of measuring contact angles is using the ‘Sessile Drop Technique’. The contact angle of a sessile drop resting on a solid surface is measured using a goniometer. The goniometer is connected to a microscope and video camera.

The drop of the prepared test liquid is released through a fine needle and allowed to drop under gravity onto the substrate whilst filming the action. From the captured image as seen in the first image above the contact angle can be measured either manually or by utilizing the software.

Sessile Drop A Typical Goniometer

Experimental work on various substrates

Below will highlight of the programme of work that we have carried out on various substrates and substances.

Several test liquids were prepared as a 0.5% solution in deionised water and some test substrates consisting of different plastics and metals were utilised.

An FTȦ 200 goniometer equipped with a digital microscope and video capture was used to analyse the sessile drop images.

A detailed list of substrates tested and their recommendations:

Substrate | 1st Choice | Biobased |

Acetal | Lanwet JH1 | Bioloop 56L or T48 |

Acrylic Sheet | Lanwet JH1 | Bioloop 56L or T48 |

Aluminium | Lanwet JH1 | Bioloop 56L |

Copper | Lanwet JH1 | |

Galvanised Steel | Lanwet JH1 | |

Glass | Lanwet JH1 | Bioloop 84L or T45 |

Karndean | Lanwet JH1 | |

Lino | Lanwet JH1 | |

Nylon 6 | Lanwet JH1 | Bioloop 68L or T25 |

Nylon 66 | Lanwet JH1 | Bioloop 56L, T25 or T48 |

PE 1000 | Lanwet JH1 | |

PET G | Lanwet JH1 | Bioloop 56L |

Polycarbonate | Bioloop 56L | Bioloop 56L or 68L |

Polypropylene | Lanwet JH1 | Bioloop 56L |

PTFE | Lanwet JH1 | |

Rigid PVC | Lanwet JH1 | |

Stainless steel | Lanwet JH1 | |

Vinyl Flooring | Lanwet JH1 | Bioloop T65 |

The following photo stills show the test liquid sessile drop after 5 seconds of wetting on a variety of substrates:

Acetal

Acrylic Sheet

Aluminium

Copper

Glass

Galvanised Steel

Karndean Flooring

Lino

Nylon 6

Nylon 66

Polyethylene (PE1000)

PET-G

Polycarbonate

Polypropylene

PTFE

Rigid PVC

Stainless Steel

Vinyl Flooring

Featured Products: Lanwet JH1, BioLoop 56L, BioLoop 68L, BioLoop 84L,

Comments